- Rémi

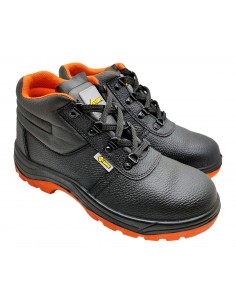

- Chaussures de sécurité

- 24 likes

- 91304 views

- 0 comments

EUROPEAN STANDARDS FOR SAFETY SHOES

The EN ISO 20345 are the European standards for safety shoes. They consist of the SB, S1, S1P, S2, S3, S4 and S5 standards.

These shoe standards are all able to resist an impact of 200 Joules and a crash of 15 kN. However, they each have individual features that characterize and differentiate them.

THE DIFFERENCE BETWEEN S1P AND S3 STANDARDS

The S1P standard refers to safety shoes that are appropriate for dry working environments and indoor tasks. This range of shoes can also be worn in the presence of fuel and oil.

S1P = A + FO + E + P

- A = antistatic

- FO = resistance to fuel and oil

- E = energy absorption at heel

- P = penetration resistance

Characteristics of S1P shoes:

- Comfort

- Anti-penetration

- Anti-perforation

- Anti-slip

- Anti-shock

The S3 standard applies to a range of safety shoes that are designed for outdoor use and wet working environments. They are also compatible with areas that are exposed to fuel and oil.

S3 = A + FO + E + WRU + P

- A = antistatic

- FO = resistance to fuel and oil

- E = energy absoption at heel

- WRU = water resistance

- P = penetration resistance

Characteristics of S3 shoes:

- Comfort

- Anti-penetration

- Anti-perforation

- Anti-slip

- Anti-shock

- Water resistance

There are two main differences between S1P and S3 standards:

- The work environment: S1P safety shoes are designed for indoor use, while S3 safety shoes are intended for outside work.

- Technical properties: S1P and S3 standards have very similar properties. But, the main difference that we can find on S3 shoes is their high resistance to water and heat.

HOW TO CHOOSE BETWEEN S1P AND S3 SAFETY SHOES

The choice between S1P and S3 safety shoes should be based on several factors. Your choice of safety shoes should respect the applicable standards if regulations exist in the industry. When there aren't any specific regulations in place, the choice between S1P and S3 shoes can be based on the type of work and required mobility, the working environment, the expected comfort and the price of the shoe model.

Some sectors with specific safety shoe standards:

- NF EN 50321 for electricians: antistatic soles must be used for electric isolation.

- EN 13832 for chemical industries: mandatory use of a safety toecap to prevent the penetration of chemical

substances.

- DIN EN 15090 for firefighters : The fabrics on firefighter boots must be leather, solid rubber or polymer. This range of safety shoes can be worn in the cases of fire, outdoor interventions and all sorts of rescue missions.

CHOOSING THE S1P STANDARD

S1P shoes are well-adapted for the construction sector. Despite having many similarities with the S3 standard, S1P safety shoes are often less expensive. Thus, they are convenient for construction companies that employ a large number of workers. S1P shoes are best-suited for workers that are looking for quality safety shoes and affordable prices. They can also be used in steel factories and various other industries. Moreover, they can be worn by electricians and first aid workers.

Our shoes S1P :

CHOOSING THE S3 STANDARD .jpg)

Unlike the S1P standard, S3 safety shoes are water resistant. Thus, they are ideal for outdoor work and humid environments. Their ability to withstand high temperatures also makes them suitable for workers that are exposed to heat and fire (welders, foundry workers..). S3 shoes are often more expensive than S1P shoes due to their superior quality. Therefore, they are indispensable for large industries that require excellent quality for their protective gear.

Comments (0)